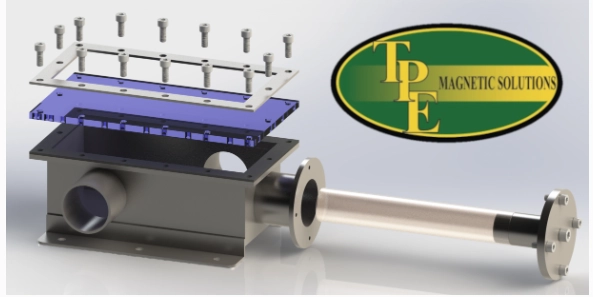

Can Turning Magnets

Orient cans/jars on conveyors (invert or upright) for washing, filling and mixing without mechanical damage.

- Food & beverage lines; gentle handling at speed

- Custom footprints for existing conveyors

- Adjustable magnet arrays for product size range